2025-10-14

Munich Airport, one of Europe’s busiest aviation hubs, is renowned for its commitment to environmental protection and operational excellence. Like all major airports conducting high-volume aircraft refueling operations, Munich Airport manages the collection and treatment of oil-water mixtures that result from routine refueling activities. Recognizing an opportunity to enhance both operational efficiency and environmental performance, the airport sought to optimize their existing oil-water separation processes.

KEY PAIN POINTS:

• Fuel Drips During Operations: During aircraft refueling, small amounts of fuel drip from couplings and pit valves while hoses are being connected or disconnected. This fuel mixes with rain or surface water and accumulates in the hydrant pits, resulting in an oily water mixture that requires effective management.

• Inefficient Existing Process: The airport’s previous solution involved using service vehicles to vacuum out the oil-water mixture and transport it to the fuel depot for separation. The mixture is characterized by a relatively high content of kerosene and solids. When transferred into a standard oil-water separator, the maximum oil retention capacity and solids loading are quickly reached. This leads to high operating costs due to increased labor and frequent maintenance interruptions.

• Regulatory Compliance Pressure: The airport must ensure full compliance with German environmental regulations, particularly the Federal Water Act (WHG) and the related Ordinance on Systems for Handling Substances Hazardous to Water (AwSV).

PROJECT OBJECTIVES:

The airport’s primary goals for this project included:

• Efficient Oil-Water Separation: Implement a highly efficient system to separate kerosene from water while ensuring full compliance with German environmental regulations.

• Effective Separation and Removal of Solids: Ensure consistent capture and elimination of solid contaminants from the mixture to improve overall treatment efficiency.

• Seamless Integration: Incorporate a solution into the existing fuel handling and wastewater infrastructure with minimal operational disruption.

• Cost Optimization: Achieve lower operating costs while enhancing environmental performance.

Facet Filtration provided a custom-engineered MAS 22.14 oil-water separator specifically designed to meet the airport’s unique operational requirements. The MAS System enabled Munich Airport to discharge treated water directly into their existing runoff infrastructure, eliminating the complex and costly previous process of collecting, transporting, and processing contaminated water at remote tank farm facilities. MAS Systems require no consumables, have no moving parts, and operate continuously without manual intervention.

SOLUTION ADVANTAGES:

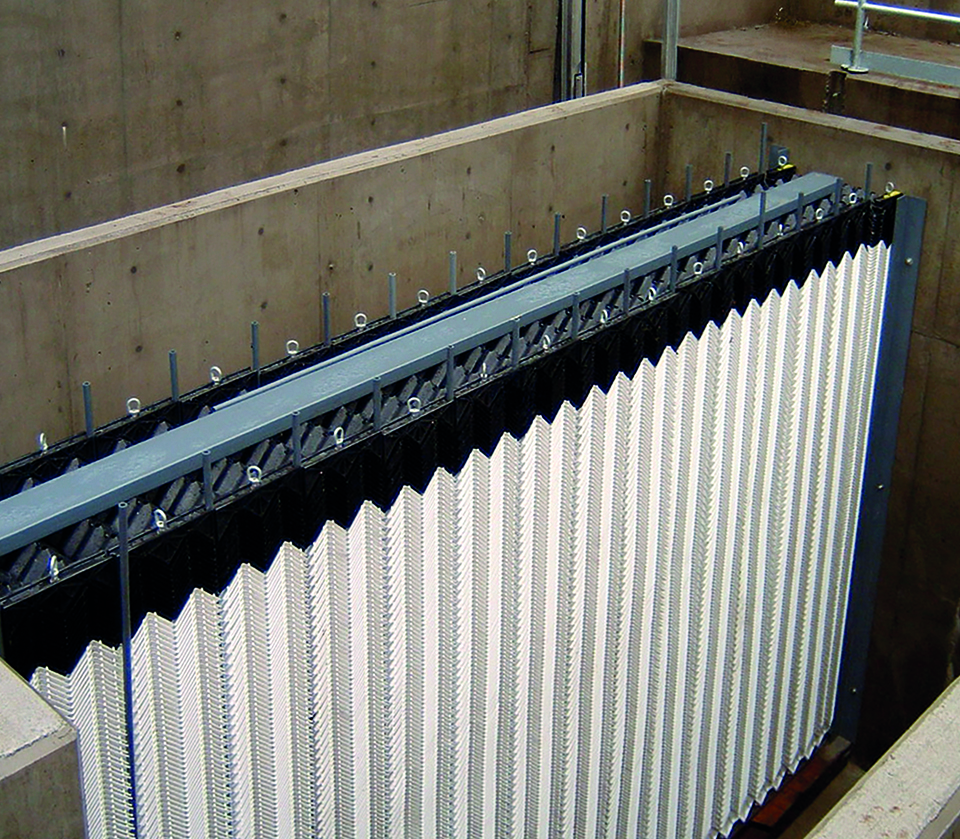

• Exclusive MPak Technology: Facet’s advanced MPak technology delivers industry-leading separation efficiency and reliability, specifically developed for demanding aviation environments—a key differentiator in the European market.

• Proven Performance: The MAS 22.14 provides superior separation, even with high solids content, outperforming previous methods.

• Compact Design: The system’s space-saving design enables easy installation into the existing infrastructure without significant operational disruptions.

• Low Maintenance Requirements: Engineered for minimal servicing, helping to reduce downtime and long-term costs.

• Custom Engineering: Tailored to the airport’s specific challenges regarding solid contamination and separation performance.

• Cost Efficiency: Enables significant cost savings compared to the previous process, while delivering improved environmental outcomes.

RESULTS & IMPACT:

• Enhanced Environmental Protection: Superior separation performance prevents contamination

• Regulatory Compliance: Full adherence to German environmental standards

• Operational Efficiency: Optimized process for effective removal of kerosene and solids

• Reduced Maintenance: Minimal system servicing requirements reduce operational disruptions

• Cost Savings: Significant reduction in operational costs compared to previous methods

This successful implementation underscores Facet Filtration’s commitment to supporting the aviation industry with innovative environmental solutions. Our unique technology, combined with a with deep knowledge of regulatory and operational requirements, ensures that airports can maintain the highest standards of safety, compliance, and environmental responsibility.

Download This Case Study