Aviation Filter Housings

For decades, our engineers have researched, designed and developed filter cartridges with increasing expansive ranges of applications. Our cartridge housings meet, or exceed, environmental and cleanliness standards required of all aviation fuels. We offer on-site filter testing labs and services, process and tech support for our extensive applications. We are committed to delivering solutions that are specifically designed for each customer’s needs.

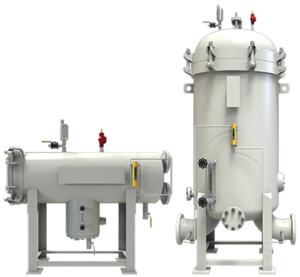

Vertical & horizontal configurations available

Vertical & horizontal configurations available Small, economical, carbon steel housings designed for in-line removal of solids

Small, economical, carbon steel housings designed for in-line removal of solids NEW DESIGN. Quick open swing bolt type closer

NEW DESIGN. Quick open swing bolt type closer Vertical & horizontal configurations available

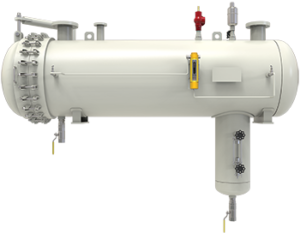

Vertical & horizontal configurations available Removes surface active agents (surfactants), color and additives from jet fuel

Removes surface active agents (surfactants), color and additives from jet fuel Designed to remove gross amounts of water and solids from hydrocarbons

Designed to remove gross amounts of water and solids from hydrocarbons